مقال لمساعدتك على فهم رقائق الألومنيوم المحبة للماء — تم نشره بواسطة Huawei Factory

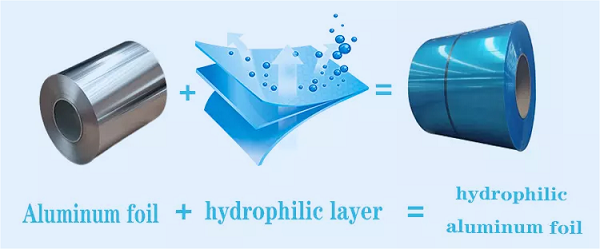

1. تعريف احباط ماء

ما هو ماء احباط? يختلف عن احباط الضوء العادي, احباط ماء, حسب الاسم المقترح, هو معالجة رقائق الألومنيوم مع الماء, ومن خلال عملية خاصة, طبقة من الطبقة المحبة للماء مغلفة على سطحها.

2. لون الرقاقة المائية

الألوان الشائعة هي الأزرق, ذهب, أسود, والألمنيوم.

3. تطبيق احباط ماء

ما هي استخدامات احباط ماء? Hydrophilic foils are usually used in heat exchangers of refrigeration equipment such as household air conditioners, refrigerators, and automotive air conditioners.

If the aluminum foil is directly used in the fins of the air conditioner, the alternating dry and wet working environment will cause it to be corroded and produce “white rust”, which will cause mold to grow in the heat exchanger, and cause environmental pollution as the cold air is sent into the room.

لا تعمل الطبقة المحبة للماء فقط على تحسين مقاومة التآكل لرقائق الألومنيوم, ولكن أيضًا يسهل على الرطوبة الموجودة في الهواء الساخن أن تتكثف على زعانف التبادل الحراري لتنتشر وتتدفق إلى أسفل الورقة, وبالتالي تجنب الضرر الناجم عن الفجوة بين زعانف التبادل الحراري. قطرات الماء “كوبري” للتأثير على تأثير التهوية للمبادل الحراري, وبالتالي زيادة معدل التبادل الحراري بمقدار 5%.

4. ست مزايا للرقائق المحبة للماء

1) مضاد للتآكل

2) مكافحة العفن

3) It can improve the corrosion resistance and weather resistance of the heat exchanger and prolong the service life of the heat exchanger

4) Due to the absence of water droplets, the noise generated by the vibration of the air conditioner can be reduced accordingly

5) Dust removal

6) No smell

5. Common alloy state of hydrophilic foil

At present, there are many 8011 alloys on the market, and a small number of customers will ask for 1-series and 3-series aluminum foils, مثل 1100 رقائق الألومنيوم و 3102 ورق ألومنيوم, و 8011 aluminum foil is more common.

حِدّة: O state or H22, these two states are relatively common, a small number of customers require 8011 H24 or H26, and provide according to customer requirements.

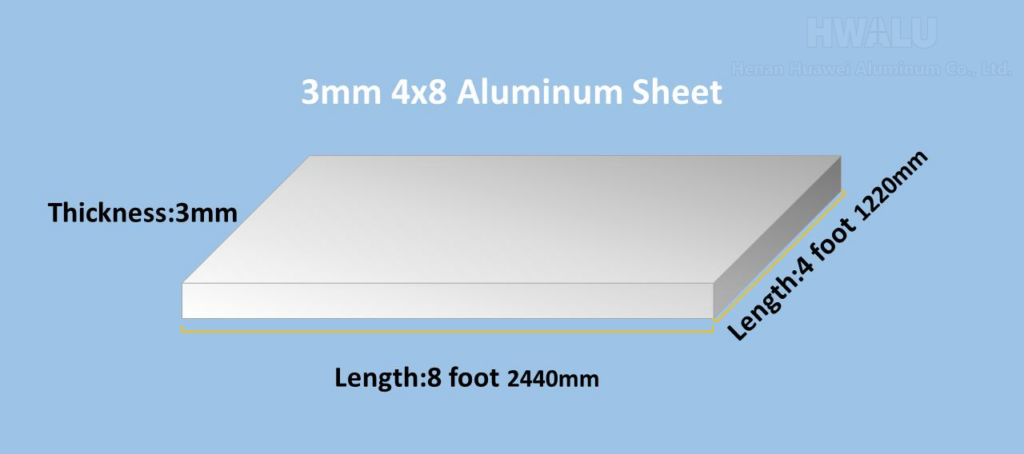

6. Common specifications of hydrophilic foil

0.08-0.2*250-1600MM

Common thickness: 0.095, 0.12, 0.13, 0.18MM, إلخ.

Common width: 277, 286, 470, 774, 835MM, إلخ.

7. Hydrophilic foil structure

Hydrophilic coating + corrosion-resistant coating + ورق ألومنيوم + corrosion-resistant coating + hydrophilic coating

8. Classification of hydrophilic coating

عمومًا, a simple distinction can be made between inorganic coatings and organic coatings

Organic coatings can be divided into: general organic coatings, high corrosion-resistant organic coatings, antibacterial organic coatings and high corrosion-resistant antibacterial coatings.

Inorganic coating material: water glass or silica

Organic coating material: hydrophilic resin

9. Different coating characteristics of hydrophilic foil

Organic coating: The hydrophilicity of the coating film is relatively poor, but the formability, corrosion resistance and odorlessness of the coating film are excellent, and the price is relatively high.

Inorganic coating: The hydrophilicity of the coating film is relatively good, but the corrosion resistance and odorlessness are poor, and the price is relatively cheap.

At present, organic coatings are widely used in the market, and all of them have antibacterial function.

10. Performance requirements of hydrophilic foil

Usually the indicators for testing hydrophilic foil are as follows:

Substrate quality (according to YS/T95.1), special standard for air-conditioning foil.

Chemical composition (according to GB/T3190)

الخواص الميكانيكية (according to 3.3 و 3.4 in YS/T95.1)

Coating properties (according to YS/T95.1)

Appearance quality (according to 3.6 in YS/T95.1)

11. Introduction to the properties of hydrophilic foil coating

1) General organic coating requirements:

| Number | العنصر | Technical Indicators |

| 1 | Film weight | 1.0~1.5g/m2 (average on one side) |

| 2 | initial hydrophilic angle

Persistent hydrophilic angle |

Initial hydrophilic angle≤10°

Persistent hydrophilic angle≤30° |

| 3 | Adhesion | Cupping test (indentation depth: 5مم): no peeling Cross-cut test (cross-cut interval 1mm): 0 grade |

| 4 | Corrosion resistance | Neutral salt spray test (500h) R.NO.≥9.5 |

| 5 | Alkali resistance | Sample coating without white or black spots |

| 6 | Solvent resistance | Sample weight loss ≤ 1% |

| 7 | heat resistance | At a temperature of 200 ° C, keep for 5 الدقائق, the color does not change; At a temperature of 300°C, keep it for 5 الدقائق, the coating film is slightly yellow |

| 8 | oil resistance | Soak in no-cleaning oil for 24 ساعات: the coating does not bubble Hydrophilic angle ≤ 20° after oil-resistant process |

| 9 | coating smell | odorless |

| 10 | wear on mold | Same as regular aluminum foil |

| 11 | Resistant to neutral detergent | Coating does not blister |

| 12 | Solvent Wipe Resistant | ≥30 times |

2) High corrosion resistance organic coating:

12. What should be paid attention to when purchasing hydrophilic aluminum foil?

1. Hydrophilicity

2. Adhesion

3. Corrosion resistance

4. Alkali resistance

5. Coating smell

6. Antibacterial properties

As a professional aluminum foil manufacturer, Huawei can help you understand hydrophilic aluminum foil more completely.