1050 aluminum disc circle material introduction

Qu'est-ce que 1050 aluminum disc? 1050 aluminum disc is a kind of industrial pure aluminum, containing more than 99.5% aluminium (belonging to 1000 or 1xxx series). 1050 aluminum plate has the characteristics of high plasticity, résistance à la corrosion, good electrical and thermal conductivity, but low strength. 1050 aluminum circles are trimmed and cut from thin aluminum sheets, usually formed by extrusion or rolling. Has a wide range of applications.

1050 aluminum disc element content

| Alliage | Et | Fe | Cu | Mn | mg | Dans | De | Cr | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | / | 99.5 |

Aluminum circle 1050 parameters:

Produit :1050 aluminum circle disc

Caractère: O, H12/H22, H14/H24/H16/H26, H32, H34, T6, T651, H111, H112, H116, H321

Épaisseur :0.3millimètre-6.0mm

Diamètre :80-1700millimètre

Delivery time: within 30-45 days after receipt of 30% acompte

Emballage: standard export wooden pallet or according to customer requirements

Surface: The surface is bright and smooth, without defects such as white rust, oil spots, and edge damage.

Applications: reflective sign boards, road furniture, tableware, sandwitch bottoms, ustensiles de cuisine, non-stick pans, etc.

Taper: Circle, Feuille, Coil, Plaque, Strip

Classification and comparison of aluminum circle materials

| Contrast Dimensions | Cast Rolling | Continuous casting and rolling | Small hot rolled | Hot rolled |

| Common alloy | 1050/1060/1100 | 1050/1060/1100/3003 | 3003 | 3003/5454/5754/6061 |

| Common post-processing | Spinning, partial deep drawing (need to refer to the finished product size) | Spinning, deep drawing | deep drawing | deep drawing |

| Common finished surface treatment | Ordinary pots and utensils with sandblasting, polishing, light oxidation, and baking varnish on the surface | Surface sandblasting, polishing, shallow oxidation, baking varnish, enrobage, silk screen printing are all available | Surface oxidation, enrobage, silk screen printing and baking paint are all available | Surface anodizing, coating and silk screen printing are all available |

| Represent pot | Ordinary set of pots, aluminum pots, steamer sieves, etc. | Ordinary set of pots, aluminum pots, steamer sieves, rice cookers | Teflon coated wok, deep pan | Teflon internally coated silk screen externally coated container, high pressure container |

| Advantages and disadvantages | The processing cost is low and the MOQ is low, the performance is not as stable as hot-rolled material, and there are more concerns about deep drawing, so it cannot be used in the production of pressure cookers and coated cookware; | The performance is close to hot rolling, but the processing cost is cheap (casting and rolling +800); the surface color difference is obvious and the coil width is fixed at 1305 millimètre, and there is a requirement for adaptability to the diameter of aluminum discs, MoQ 6-9 tons/billet | The performance is the same as that of hot rolling, but the surface is poor, and the finished product is gray; the processing fee currently known is not significantly different from that of hot rolling (¥200/ton) | Good and stable performance, high processing yield, high temperature and pressure resistance, but high price (casting + 2600) MOQ high |

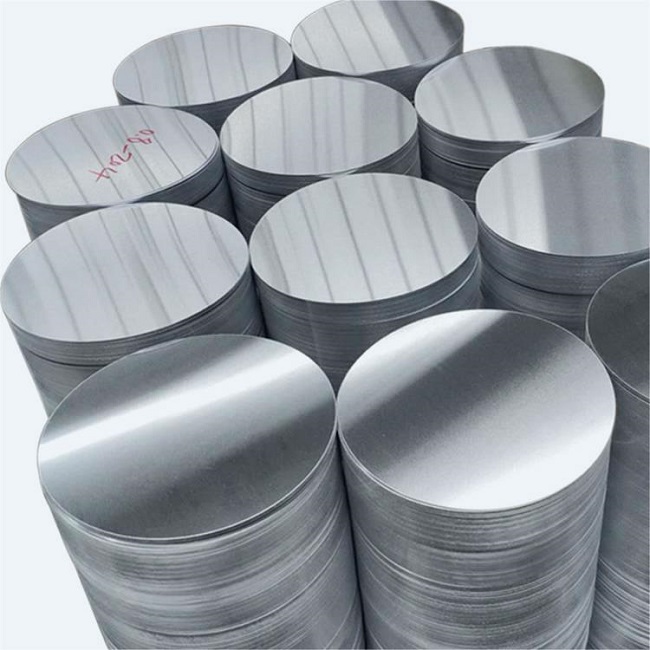

1050 aluminum circle factory

Huawei is an aluminum wafer supplier with 22 years of production experience, exporting aluminum wafers to other places all the year round. We can guarantee high-quality products and professional pre-sales and after-sales services. Guaranteed to the buyer to do the following:

1. Guaranteed to be the source factory.

2. The product supports customization.

3. Possess excellent technology and advanced and perfect equipment.

4. Available in various sizes and specifications.

5. The produced wafers are pressure-resistant and drop-resistant

6. Various crafts in the factory area

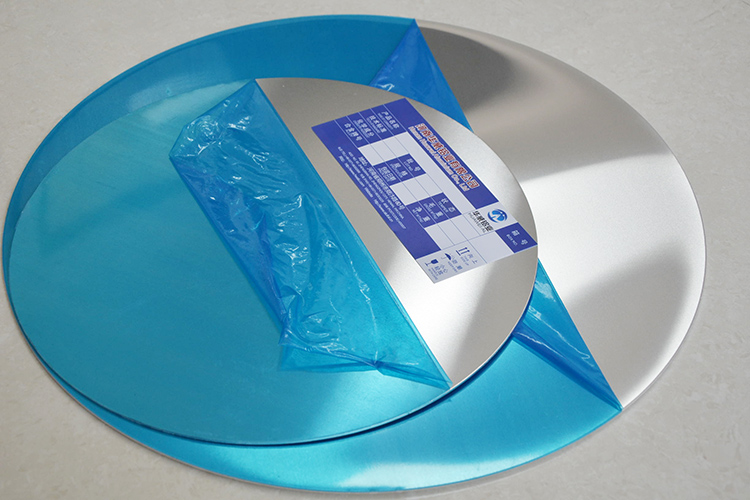

What are the protective films for 1050 aluminum wafers?

Blue film, electrostatic blue film, transparent film, black and white film, laser film, paper clip, stamping film, stretch film.

Quelle est la différence entre 1050 aluminum disc and 3003 disc?

1050 aluminium contre 3003 aluminum circles

| Série | Caractère | Alliage | Fonctionnalités | Applications |

| 1000 série |

O

H12 H24 H16 H18 H111 H112

|

1050 circles | 1. Aluminum content: >99%, excellent formability 2. High reflectivity 3. Surface anodic oxidation is stable |

1. Ordinary cooking utensils: post-processing: sanding, sandblasting, extruding pot lids; aluminum pots; 2. Lighting accessories: downlights, laminated lights, lampshades for street lights, etc. 3. Instruction signs and building materials: traffic signs, murs-rideaux, plafonds |

| 3000 série | 3003 cercle en aluminium | 1. Excellent formability 2. High elongation, can be used in deep drawing process 3. High grain grade, smooth surface and high reflectivity |

1. Advanced cooking utensils: post-processing: anodisation, enamel, spraying, deep drawing, etc.; non-stick pan; pressure cooker; 2. Lighting accessories: downlights, laminated lights, lampshades for street lights, etc. 3. Instruction signs and building materials: traffic signs, murs-rideaux, plafonds |

1050 aluminum circle CC/DC advantages

The wafers supplied by Huawei aluminum circle 1050 factory have the following advantages:

1. Alliage 1050 plaque d'aluminium, good drawing quality,

2. The spinning quality of the wafer is good, the shape is good, and there are no four ears;

3. 1050 wafers have good reflective properties and are good for polishing;

4. Disc 1050 anodizing quality is good, suitable for hard anodizing and enamel;

5. The surface is smooth, the edges are smooth, and the hot rolling quality is good.

6. The grain of the wafer is fine, and there is no bending line after deep drawing;

Aluminum circle packaging

Loading: self-stacking, the loading limit of 20-foot container is 27.5 tonnes. Pay attention to the wooden pallet.

Countries where Huawei 1050 wafers are popular

| Angola | Burkina Faso | Burundi | Nepal | Arabie Saoudite |

| Yémen | Ethiopie | Guinea | Inde | Turquie |

| Gabon | Gabon | Kenya | Chili | Bengladesh |

| Maroc | Tunisia | Zambia | Bolivia | Colombia |

Applications and uses of 1050 cercle en aluminium

Aluminium 1050 circle is widely used in deep drawing cookware, spinning cookware, road signs, building materials, insulation materials, traffic signs, etc.

Commentaires

Il n'y a pas encore de critiques.