Co robi 1060 aluminum plate alloy mean?

1060 belongs to the 1000 series pure aluminum with an aluminum content of up to 99.60% (standard: GB/T3190-2008), and has similar aluminum content and metal characteristics with pure 1050 arkusz aluminium. It also has the characteristics of high metal processing plasticity, weather resistance, good electrical conductivity and thermal conductivity.

1060 aluminum plate also has its shortcomings. Stop 1060 aluminum has low strength and cannot be strengthened by heat treatment.

Dlatego, 1060 aluminum sheet has many applications in capacitors, electronic tube isolation nets, wire and cable protective sleeves, nets, wire cores and aircraft ventilation system parts.

1060 aluminum sheet chemical element content

| Stop | I | Fe | Cu | Mn | Mg | Zn | Z | Kr | Glin |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | / | Pozostać |

Mechanical properties of 1060 arkusz aluminium

| Stop&Hartować | Wytrzymałość na rozciąganie( Rm/Mpa) | Rp0.2/Mpa | Elongation/% | Hardness / HBWα |

| 1060-H24 | 110-136 | 75 | 3 | 22-26 |

| 1060 H22 | 112-130 | 78 | 3 | 12-16 |

| 1060 H18 | 110-130 | 80 | 3 | 22-30 |

| 1060 O | 96-120 | 82 | 3 | 10-16 |

Co jest 1060 Aluminium alloy used for?

1060 aluminum sheet is widely used in products that do not require high strength. Products are commonly used in signboards, billboardy, building exterior decoration, bus body, high-rise and factory wall decoration, kitchen sinks, lamp sockets, fan blades, electronic parts, chemical equipment, części do obróbki blachy, deep drawing or spinning concave Shaped utensils, welded parts, heat exchangers, clock and disk surfaces, nameplates, kitchenware, decorations, reflective appliances, itp.

1060 aluminum plate used for billboard nameplate

1060 aluminum sheet for building exterior

1060 aluminum plate for kitchen utensils

1060 aluminum plate for chemical equipment

1060 aluminum plate heat treatment method

1. Rapid annealing: the heating temperature is 350-410℃; the holding time is between 30-120min depending on the effective thickness of the material; air or water cooling.

2. High temperature annealing: the heating temperature is 350~500℃; when the thickness of the finished product is ≥6mm, the holding time is 10~30min, and when it is less than 6mm, the heat is penetrated; air cooling.

3. Low temperature annealing: heating temperature 150 ~ 250 ℃; holding time 2 ~ 3h; air or water cooling.

Huawei 1060 aluminum sheet product production requirements

As a large aluminum alloy raw material supplier, Huawei Aluminum has always put product quality first. Our products will strictly meet the following requirements.

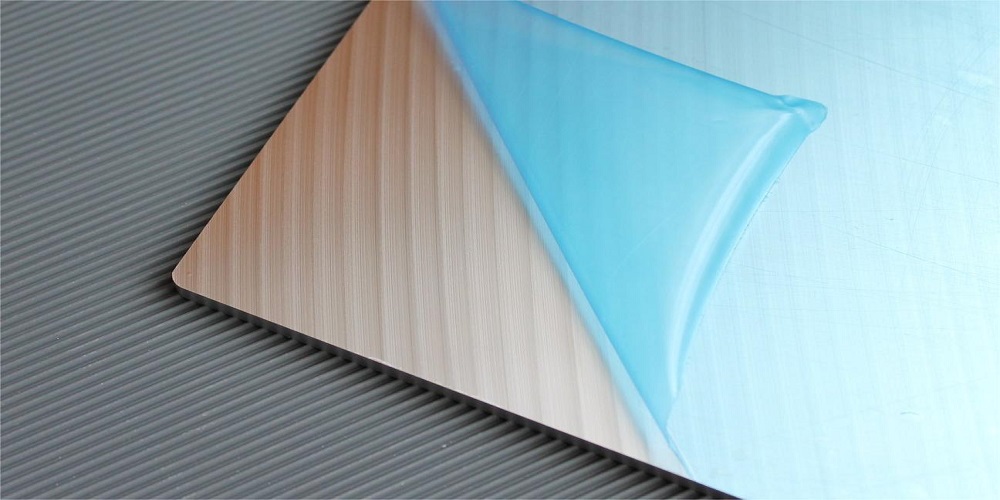

1. The surface of the 1060 aluminum plate should be clean, and no cracks and oxidized debris are allowed.

2. The surface of the 1060 aluminum plate is allowed to have defects such as indentation, scratches, rolling indentations, itp., but the depth cannot exceed the allowable negative deviation of the plate, and the minimum thickness is guaranteed.

3. The process clad aluminum thick plate is allowed to have the shedding part of the cladding layer and the air bubbles of the cladding layer.

4. The surface of the plate 1060 allows to repair the defects within the range of thickness difference.

5. Other requirements for aluminum plate production: the demander and the supplier will formulate them themselves.

Opinie

Nie ma jeszcze recenzji.