Common uses for aluminum sheets are:

1-8 series aluminum alloy plates are often used in lighting; solar reflectors; building decoration; interior decoration: techos, walls, etc.; furniture, cabinets; elevators; señales, placas de identificación, bags; interior and exterior decoration of cars; interior decorations: such as photo frames , aluminum plate painting, relief, etc.; electrodomésticos: refrigeradores, microwave ovens, audio equipment, etc.; aerospace and military aspects, such as China’s large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc.; procesamiento de piezas mecánicas; mold manufacturing; chemical industry, insulation pipes cladding;

Aluminum plates are usually divided into the following two types:

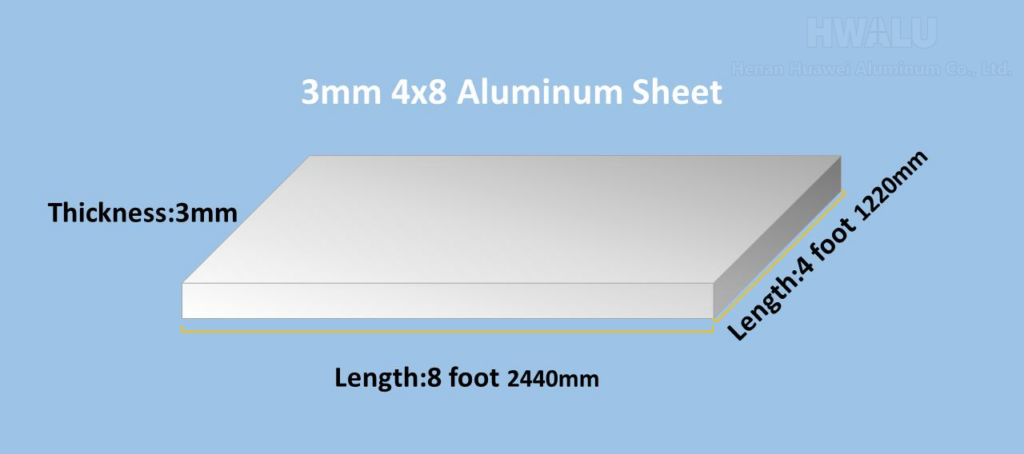

1. Divided by thickness: (unit: milímetro)

Thin plate (hoja de aluminio) 0.15-2.0

Regular plate (hoja de aluminio) 2.0-6.0

Medium plate (plato de aluminio) 6.0-25.0

Thick plate (plato de aluminio) 25-200 super thick plate above 200

2. According to the alloy composition, it is divided into:

High-purity aluminum plate (rolled from high-purity aluminum with a content of more than 99.9%)

Placa de aluminio puro (the composition is basically rolled from pure aluminum)

placa de aleación de aluminio (composed of aluminum and auxiliary alloys, usually aluminum-copper, aluminum-manganese, aluminum-silicon, aluminum-magnesium, etc.)

Composite aluminum plate or brazing plate (special-purpose aluminum plate material obtained by compounding multiple materials)

Aluminum-clad aluminum plate (aluminum plate is clad with thin aluminum plate for special purpose)

In the aluminum alloy, the grade is representative. The following is an example based on the grade of 7075T651 aluminum plate. El primero 7 represents the group of aluminum and aluminum alloys – aluminum-zinc-magnesium alloys. The aluminum and aluminum alloy groups are divided into nine categories. Entre ellos, 1, 3, 5, 6, y 7 series of aluminum and aluminum alloys are the main ones, and among them, 1 series and 3 series aluminum plates are the most commonly used, y es menos probable que otras series se utilicen en el uso real.

la primera categoria: 1 serie: aluminio puro industrial

la segunda categoria: 2 serie: aleación de aluminio y cobre

La tercera categoría: 3 serie: aleación de aluminio manganeso

La cuarta categoría: 4 serie: aleación de aluminio y silicio

La quinta categoría: 5 serie: aleación de aluminio y magnesio

La sexta categoría: 6 serie: aleación de aluminio-magnesio-silicio

La séptima categoría: 7 serie: Aleación Al-Zn-Mg-Cu

La octava categoría: 8 serie: otras aleaciones

Novena categoría: 9 serie: aleación de repuesto

Requisitos técnicos de calidad de la placa de aluminio.:

1. The most basic point is that the surface of the plate must be clean, and no cracks or other oxidized impurities are allowed.

2. Due to the imperfection of the process, the surface of the plate is allowed to have defects such as dents, scratches or roll marks, but its depth must not exceed the allowable negative deviation of the plate. If the deviation exceeds the value, it will be remade.

3. Process Aluminum-clad thick plates are allowed to have shedding parts of the cladding layer and bubbles in the cladding layer.

4. Under normal circumstances, the surface of the plate is allowed to repair and remove defects within the range of thickness difference.

5. Some other requirements are mainly drawn up with the demanders and suppliers themselves, and then the process is changed.

The above is about the quality requirements on the surface of the aluminum plate. Although there may be certain errors due to some reasons, it must not exceed the controllable deviation value.